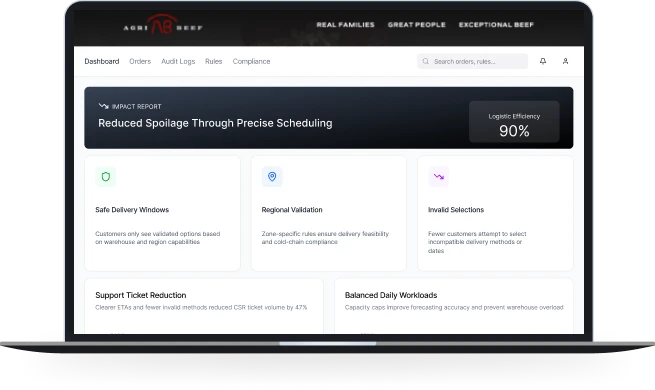

Agri Beef is a family-owned, vertically integrated beef producer operating across the Pacific Northwest. They manage every stage of production, supplying premium beef through brands like Snake River Farms, Double R Ranch, St. Helens Beef, and Rancho El Oro. Their ranch-to-table model supports both B2B and DTC channels, including ecommerce operations that demand precise, delivery-safe fulfillment. Folio3 worked as a trusted Snake River Farms development partner, supporting Agribeef’s broader ecommerce and fulfillment requirements across its multi-brand operation.

Agri Beef dealt with spoilage risk, inconsistent ETAs, and a lack of control over how shipping options appeared to customers. Rigid platform limits caused incorrect delivery windows, unavailable methods, and rising CSR workload. Seasonal, geographic, and warehouse-level rules were difficult to enforce, increasing operational strain and reducing customer clarity during checkout.

Spoilage increased when deliveries landed outside safe transit windows. The team needed a way to restrict dates and methods automatically to avoid unsafe timelines.

The business required predictable blackout controls for weather, holidays, and regional constraints, but lacked tools to enforce them consistently.

Different fulfillment centers used varied cutoff times, creating incorrect ETAs and customer confusion around shipping commitments.

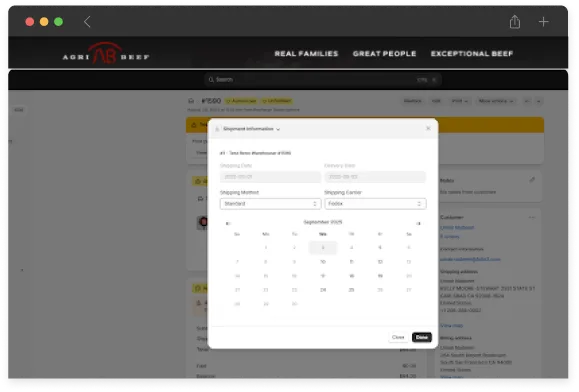

Post-checkout corrections required repeated manual checks and overrides, slowing fulfillment and increasing mistakes.

Customers often saw shipping methods that were unavailable or unsafe for their region, causing fulfillment errors and last-minute adjustments.

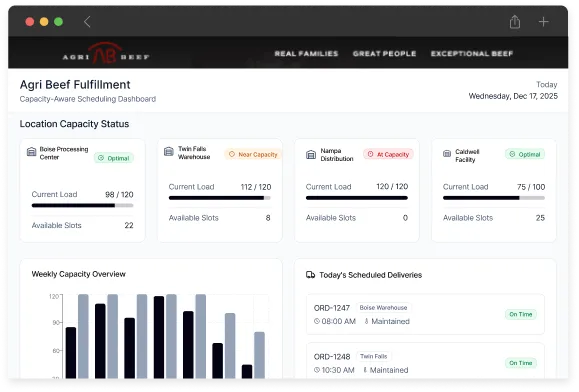

Without daily caps per warehouse, overbooking created backlogs and unpredictable fulfillment scheduling.

We provide logic tailored to perishable ecommerce where delivery timing directly affects product safety.

Our rule engine supports warehouse-level cutoffs, blackouts, and method visibility without relying on external apps.

We work natively with Checkout UI Extensions and Delivery Customization Functions, reducing friction and platform constraints.

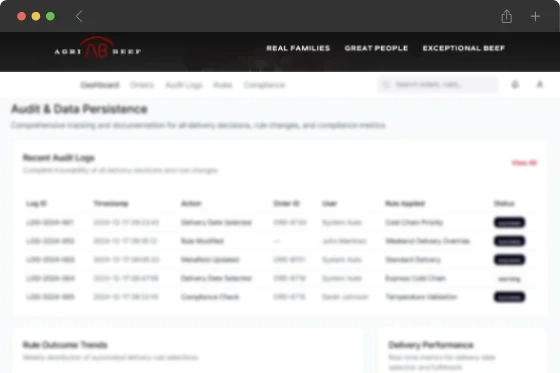

Admin logs, order-level date storage, and CSR tools addressed visibility and workflow concerns.

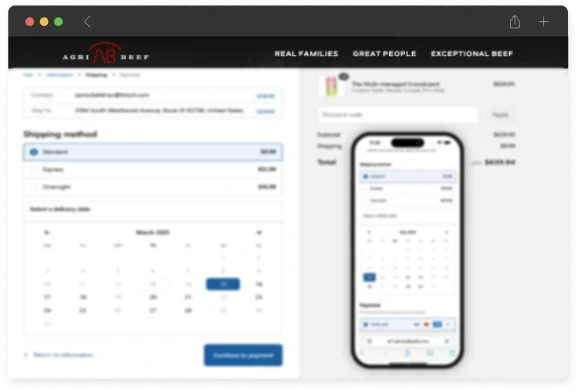

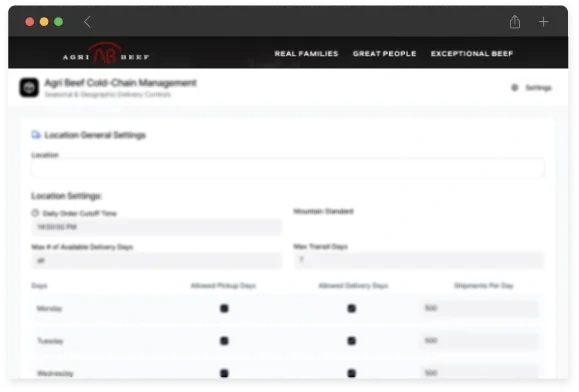

Agri Beef required a calendar that could protect cold-chain timing while staying consistent across multiple warehouses. We built a rules-driven system that evaluates cutoff times, transit limits, carriers, and the fulfillment location before presenting any dates. Each option shown to the customer reflects a safe delivery window supported by real operational constraints. This ensured every order delivery date shown is valid and aligned with cold chain requirements, while the underlying shipment calendar dynamically adjusts based on warehouse and carrier logic.

Agri Beef’s fulfillment network operates across several time zones, each with unique capacity, carriers, and shipping behavior. We introduced warehouse-specific logic that evaluates an order’s assigned location independently, ensuring only accurate methods and dates appear during checkout. This removed conflicting ETAs created by generalized settings and aligned customer expectations with real operational timing. With this structure in place, warehouse routing became more consistent, deliveries matched intended schedules, and the business gained reliable control over how each location presents shipping options. As an ongoing Agribeef development partner, Folio3 ensured this logic scaled cleanly across both B2B and DTC flows.

Cold-chain fulfillment demands predictable rules when weather, holidays, or regional limitations affect delivery safety. We expanded blackout controls to support date ranges, states, ZIP codes, and conditions that require temporary restrictions. These rules prevent customers from selecting unsafe or unreliable delivery windows and give the team a consistent framework for adjusting availability throughout the year. By aligning checkout behavior with seasonal and geographic realities, Agri Beef reduced spoilage risk and avoided orders that could not be delivered under required temperature or timing standards.

Daily fulfillment loads vary significantly across Agri Beef’s locations, and overbooking can slow operations or jeopardize delivery timing. We added capacity-based scheduling that monitors each warehouse’s remaining slots and removes dates automatically once limits are reached. Customers then see only options that the location can realistically support. This system smooths workload distribution, helps teams plan staffing more accurately, and keeps order volume aligned with operational capability. By preventing capacity overruns, fulfillment stays predictable and cold-chain requirements remain intact.

Shipping methods differ in reliability based on warehouse, season, and destination, so we built logic that screens each option before presenting it to the customer. Unsafe, unsupported, or regionally restricted methods never appear during checkout, eliminating confusion and reducing last-minute changes by the fulfillment team. Each selection reflects constraints that matter for cold-chain delivery, such as transit duration and carrier availability. This structure simplifies decision-making for shoppers and ensures shipments move through channels that meet Agri Beef’s quality and timing standards.

Customer service teams often need to modify delivery dates, but manual changes can introduce errors when rules are not enforced. We developed an Admin extension that applies the same logic used at checkout, ensuring any CSR adjustment remains valid for the warehouse, season, and carrier involved. This reduces reliance on tribal knowledge, removes guesswork, and provides a structured way to correct orders without compromising cold-chain requirements. By standardizing post-checkout updates, the team saves time and maintains consistent operational accuracy.

Accurate recordkeeping is critical for fulfillment, compliance, and internal reviews, so we built persistent storage for every delivery date and rule outcome. Each order records the chosen date through metafields, while rule changes are logged in the Admin for traceability. This gives teams clear visibility into how selections were generated and supports audits tied to cold-chain safety and warehouse performance. The result is a transparent system that aligns operational decisions with documented logic and provides dependable reference points across the organization.

Get in touch with our Team!

3080 Yonge Street, Suite 6060, Toronto, Ontario M4N 3N1

Amado Nervo #2200, Edificio Esfera 1 piso 4, Col. Jardines del Sol, CP. 45050, Zapopan, Jalisco, Mexico

C/- Prime Partners Level 4 1 James Place, NORTH SYDNEY New South Wales 2060

160 Bovet Road, Suite # 101, San Mateo,

CA 94402 USA

6701 Koll Center Parkway, #250 Pleasanton, CA 94566

Tel: +1 (408) 412-3813

Export House, Cawsey Way, Woking, Surrey, GU21 6QX

Tel: +44 (0) 14 8339 7625

Folio3 FZ LLC, UAE, Dubai Internet City,

1st Floor, Building Number 14, Premises 105, Dubai, UAE

Tel: +971 04 2505173

49 Bacho Kiro Street, Sofia 1000, Bulgaria

Folio3 Pvt. Ltd, Folio3 Tower, Plot 26, Block B,

SMCH Society, Main Shahrah-e-Faisal, Karachi.

Tel: +92-21-3432 3721-4

First Floor, Blue Mall 8-R, MM Alam Road Gulberg III, Lahore

Corporate 7 by Maaksons, Executive Block, Civic Center 1, Gulberg Green, Islamabad

Tel: 0333 5657425

Set up your Shopify MCP with Folio3.